Page 191 - LIT-18626-12-95

P. 191

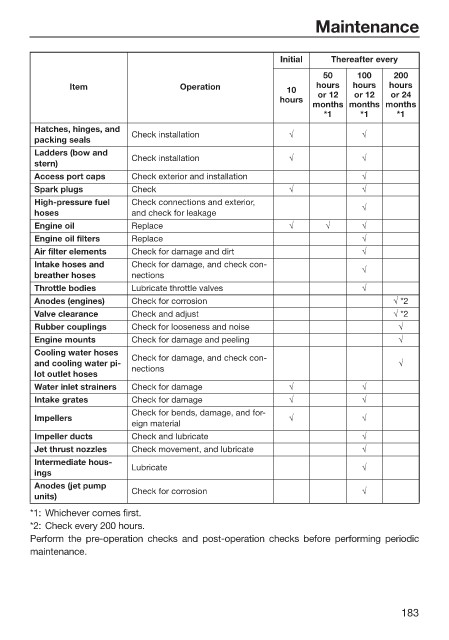

Maintenance

Initial Thereafter every

50 100 200

Item Operation hours hours hours

10

hours or 12 or 12 or 24

months months months

*1 *1 *1

Hatches, hinges, and Check installation √ √

packing seals

Ladders (bow and Check installation √ √

stern)

Access port caps Check exterior and installation √

Spark plugs Check √ √

High-pressure fuel Check connections and exterior, √

hoses and check for leakage

Engine oil Replace √ √ √

Engine oil filters Replace √

Air filter elements Check for damage and dirt √

Intake hoses and Check for damage, and check con- √

breather hoses nections

Throttle bodies Lubricate throttle valves √

Anodes (engines) Check for corrosion √ *2

Valve clearance Check and adjust √ *2

Rubber couplings Check for looseness and noise √

Engine mounts Check for damage and peeling √

Cooling water hoses Check for damage, and check con-

and cooling water pi- nections √

lot outlet hoses

Water inlet strainers Check for damage √ √

Intake grates Check for damage √ √

Check for bends, damage, and for-

Impellers √ √

eign material

Impeller ducts Check and lubricate √

Jet thrust nozzles Check movement, and lubricate √

Intermediate hous- Lubricate √

ings

Anodes (jet pump Check for corrosion √

units)

*1: Whichever comes first.

*2: Check every 200 hours.

Perform the pre-operation checks and post-operation checks before performing periodic

maintenance.

183